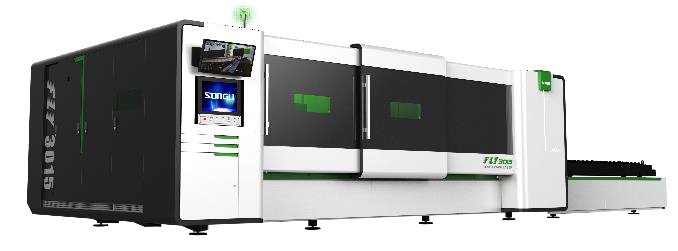

FL Open type CNC Fiber Laser Cutting Machine

Compared with other laser sources, Fiber has its own advantages below:

- Low maintenance: it’s transmitted by Fiber cable, no need reflecting mirrors, no need to adjust the light route;

- Low power consumption: Energy saving and environmentally friendly, lowest power consumption as the highest photoelectric conversion with Fiber source. Only 20%-30% consumption compared with other laser cutting system.

- Low gas consumption: no need mixed gas for cutting, high pressure air can also cut steel.

Model: FL

Material: Stainless steel, Mild steel, Aluninum,etc

Max Capacity: 500W / 750W / 1000W / 2000W / 3000W

Bamboocnc Fiber Laser Cutting Machine

- The principle of laser cutting is to focus the laser beam into very small points of light, so that the focus of a very high-power density, this is the beam input (conversion of light energy) of heat far more than the material reflection, conduction or diffusion of the part, material quickly heated to the gasification temperature, evaporation hole. As the beam and material move relatively linearly, the holes form slits of very narrow width.

- Laser cutting is the best cutting method in all kinds of cutting technologies that people have mastered nowadays. Compared with traditional cutting, the advantages of laser cutting are: small thermal deformation, high cutting accuracy, low noise, no pollution, easy to realize automatic cutting, processing cost is 50% less than that of mechanical processing.

- Fiber laser cutting machine uses imported international advanced fiber laser to output high energy density laser beam and focuses on the surface of the workpiece. It is the instantaneous melting and gasification of the area irradiated by the ultra-fine focus spot on the workpiece and realizes automatic cutting by moving the spot irradiation position through the numerical control mechanical system. It is a high-tech equipment which integrates the most advanced optical fiber laser technology, numerical control technology and precision mechanical technology.

- Double servo motor drive.

- It has higher stability, higher speed and faster acceleration.

- Full digital CNC servo motor communication.

- The new peripheral design can enter the working area of the equipment from three different directions.

- The machine adopts gantry structure, imported reducer and high-precision linear guide rail. It has smooth transmission and high precision, which greatly improves the production efficiency of the machine tool.

- The whole welding structure of the bed is adopted, rough processing is carried out after annealing, and then vibration aging treatment is carried out. The stress in welding and processing can be completely eliminated. It has good rigidity, high precision and can keep the deformation for a long time.

- Aluminum alloy beams are cast as a whole. After two high temperature annealing, rough processing and vibration aging, the beams have good rigidity, light weight and dynamic properties.

- Import high-precision electronically controlled proportional valve, precisely control the pressure of cutting auxiliary gas, in order to achieve the best cutting effect. It is much more accurate and convenient than manual pressure regulating valve.

Detailed description

- Accurl Laser Control System. Professional CAD/CAM automatic programming, software and automatic nesting software, support both Chinese and English interface, rich process parameters, to maximize the savings of raw materials.

- The function of the fiber laser cutting head is mainly to spread the very thin laser coming out of the fiber head through the beam expanding mirror to enlarge the spot, and then make the laser beam form a focus near the cutting nozzle through the focusing mirror to cut the workpiece through the auxiliary gas noise.

- The role of the chiller: laser, optical fiber head, cutting head in the work of heat, direct cooling water effect is better, the role of the chiller is cooling laser, optical fiber head, cutting head. The water requirement of the chiller is distilled water to reduce the corrosion of the inner wall of the laser.

PL CNC Table Plasma Cutting Machine

CNC plasma cutting machine also called plasma cutter, and plasma cutting is a processing method that uses the heat of a high-temperature plasma arc to partially or partially melt (and evaporate) the metal at the incision of the workpiece and uses the momentum of the high-speed plasma to remove the molten metal to form an incision.

Model: PL

Material: Stainless steel, Mild steel, Aluminum

Thickness: 0-50 mm

Working Area: 1100X2100 mm / 1600X3100 mm / 2100X4100 mm / 1600X6100 mm / 2100X6100 mm

Bamboocnc Cnc Table Plasma Cutting Machine

- Bamboo PLASMA machines are precision compact bed machine tools for high precision plasma cutting and are available in a wide range of sizes from 3 m x 1.5 m upwards.

- Designed on laser cutting machine principles, the PLASMA fully exploits the latest Hypertherm plasma cutting processes and produces clean, square, dross-free cuts on a wide range of ferrous and non-ferrous metals.

- Our customers report that components cut on the PLASMA machine with high performance plasma and True Hole technology are comparable with laser cut parts in many cases.

- Our machine design engineers have specified heavy duty precision fabricated and machined structures combined with twin hardened and ground linear bearings in all axes, powerful digital drives and precision transmissions to deliver high accuracy and repeatability and produce smooth motion with high speed and acceleration for the highest possible cut quality.

Scope of application

The full range of Hypertherm plasma cutting systems can be specified with Accurl plasma cutting machines from units designed for high-speed sheet metal cutting through to high precision systems capable of piercing and cutting 50 mm steel and beyond. Systems range in power from 30 A up to 800 A cutting current; the largest system in the range can cut stainless steel and aluminium up to 160 mm thick.

Oxy-fuel flame cutting can cut carbon steels up to 300 mm and beyond with a good, clean square cut. Cutting speeds are slower than plasma but additional cutting torches can be added at relatively low cost so multiple torches cutting can boost productivity. Advanced control systems automate the process and greatly simplify the use of this effective cutting technology.

Plate marking options for part numbers, bending lines or marking out for assembly are available on many of the machines. These additional processes can eliminate many manual marking-out tasks and save hours of production time.

- Portable monoblock construction with small footprint

- Easy installation

- Dual side AC servo Y motorization with direct planetary gear box, helical rack and pinion drive system

- Precision Linear Rail Guide Ways in X and Y axis

- High speed torch lifter with automatic arc voltage height control

- Fully enclosed hose and cable carriers

- Integrated downdraft table with CNC programmable multi zone selection

- Integrated dross bins

- Magnetic Torch anti-collision protection system

- Laser pointer for plate alignment

- CE safety specifications

Fast CAM jacking software is the dedicated drawing and nesting programming

software for numerical control flame, plasma, laser and water-jet cutting machines,

it is applied to drawing, programming, jacking, calibration and numerical control cutting

for components with arbitrary shapes, the high-end cutting processes of automatic nesting,

edge-shared and bridge connection and could be used, user could easily grasp the methods

of drawing, nesting and programming without computer foundation and CAD experience

- Support: Windows98/2000/NT/XP/vista

- Support Multi-languages: Chinese/ English/ German/ Spanish/Polish/Korea/Czech/Russian etc.

- Features: AUTOMATIC ‘EVERYTHING’: TOOL PATHING, PIERCING, SEQUENCING, NESTING, CUTLIST

- Support Chinese/ English.

- Dynamic/static processing graphics display.

- High speed 16 bits SMC Plus 8 bits SMC and hardware interpolation control, running at 0.5u equivalent weight 6000 mm/min.

- Step motor, stable movement, low noise, improving processing quality.

- Setting starting speed and lifting speed time at your will.

- Electrical gear adjustment, no need of pulse equivalent weight, any kind of machinery equipment with pitch of screws of thread stick.

- General ways, simple, flexible, accuracy and easy operation.

- Providing many kinds of fixing circle to make programming simpler.

- Directly diagnosis all inputting data of system.

- Many kinds of parameter settings can meet the different requirements.

- USB port supports program transfer.

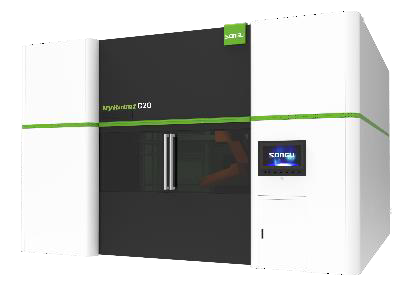

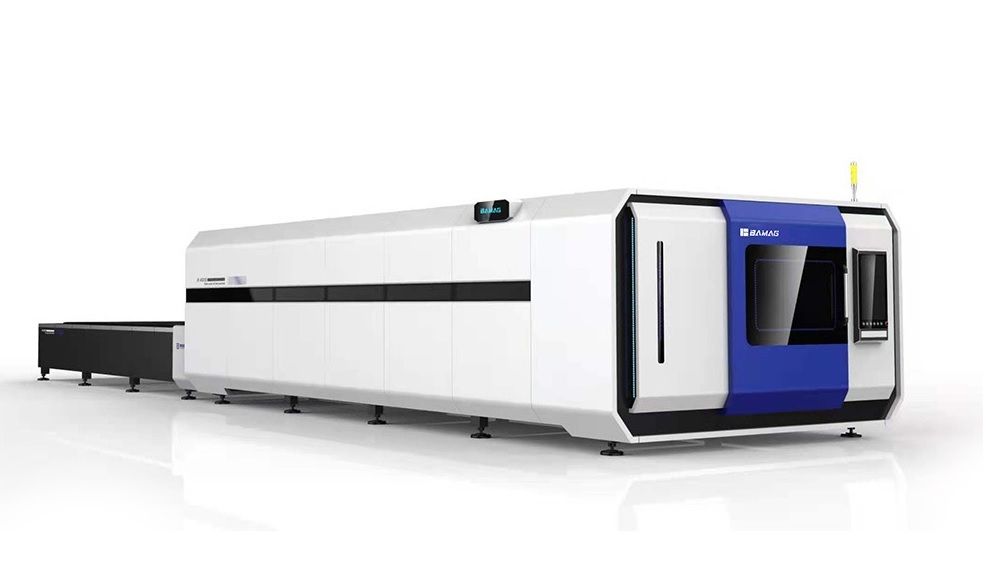

Close type CNC Fiber Laser Cutting Machine + Exchange Working Table

Closed processed environment, anti-dust, anti-smoke, safety and environment-friendly.

Entirely heavy entry structure machine body, high strength aluminum-casted gantry, good rigidity, stable performance.

Imported high precision transmission device, which is perfectly work with Servo system, thus it can make sure cutting precision and efficiency.

Professional laser cutting CNC system. Automatically track edge and lay out material. Improve the efficiency of metal utilization and production.

Optional high speed exchangeable table, simplify work process and save time.

Model: FT

Material: Stainless steel, Mild steel, Aluninum, etc.

Max Capacity: 500W—6000W

BAMBOOCNC Close Type High Speed CNC Fiber Laser Cutting Machine With Exchange Working Table

- Closed processed environment, anti-dust, anti-smoke, safety and environment friendly.

- Entirely heavy entry structure machine body, high strength aluminum-casted gantry, good rigidity, stable performance.

- Imported high precision transmission device which is perfectly work with Servo system, thus it can make sure cutting precision and efficiency.

- Professional laser cutting CNC system. Automatically track edge and lay out material. Improve the efficiency of metal utilization and production.

- Optional high speed exchangeable table, simplify work process and save time.

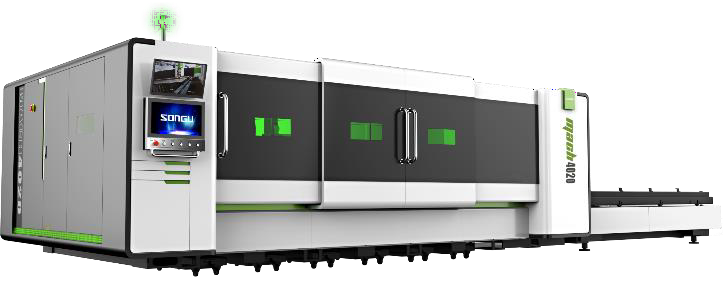

MACH Laser Cutter

Mach 3015/4020/ 6025 are our high-end fiber cutting series machines:

- Fully enclosed protection cover, comply with European safety standard;

- ALPHA direct servo motors integrates with gearhead( two sides drive system), high precision, high efficiency.

- All Germany high configuration, stable, robust and

- Side door open, easy

- Laser application parameterize design, equip with Remote Monitoring and Remote Assistance functions, more user-friendly.

- Low gas cost by precision servo gas control, low running

- Safety, beauty

- Fast, efficient, powerful

- Stable and robust

- Low running cost

- Easy operation & intelligent

- Eco laser

- Protection cover with laser radiation free watching window

- Professional industrial design, easy reach the operation area

Customer benefit:Safety and robust

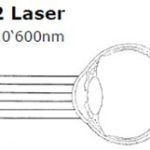

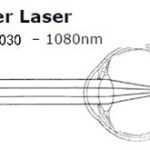

- Fiber laser wavelength close to visible light, radiation danger is 50 times higher than CO2 laser hazards;

- High power fiber laser beam can though the retina and hurt crystalline lens and eyes;

- The front door is on the Y axis, easy for