QC12Y Swing Beam Shearing Machines with E21 Controller

The hydraulic swing beam shearing machine combines performance and simplicity. The robust steel welded machine frame ensures high reliability and excellent cutting quality. The hydraulic shears for sale are engineered to have the most optimized cutting angle which provides the least distortion when cutting the widest variety of materials. The low cutting angle on this type of shears allows limiting sheet metal twist and bow.

Model: QC12Y

Material: Stainless steel, mild steel, aluminum

Thickness: 0.1-20 mm

Width: 2500-600 0mm

Controller: E21S(E200S/DAC310/DAC360S/P40 Optional)

- The hydraulic swing beam shear is the perfect solution for cutting sheet metal with thickness between 4-35mm and length from 2500 to 8000 mm.

- Adopt advanced hydraulic system, reliable and easy for maintenance.

- The rear stopper is fitted with coder and digital display system, real-time display of material position.

- Multi-step programming function, automatic operation and continuous positioning of rear baffle, automatic adjustment of position of rear baffle.

- Shear counting function, real-time display of the number of shears, power off memory after the location of the block, procedures and parameters.

- Assembly precision ball screw, linear guide rail, to ensure the positioning accuracy, high machining precision.

- Safety Standards(2006/42/EC):

1.EN 12622:2009 + A1:2013

2.EN ISO 12100:2010

3.EN 60204-1:2006+A1:2009 - Front finger Protection (Safety light curtain).

- South Korea Kacon Foot Switch (Level 4 of safety).

- Back metal safe fence with CE standards.

- Safety relay with Monitor the pedal switch and safety protection.

Detailed description

- HD LCD display, with both Chinese and English language options, a display programming parameter, faster and more convenient programming

- Back gauge control:Smart positioning, can also be manually adjusted as needed to remove the mechanical hand positioning device.

- Cut Stroke: Built-shearing time relay, simple operation, cost savings

- Shear angle: Built shear angle adjustment function, eliminating the angle indicators and buttons

- Blade gap: encoder feedback, time display blade gap size, simple operation

- Having a key parameter backup and restore functionality, you can always restore the parameters as required, reducing maintenance costs

- All keys on the panel are micro-switches, through EMC, high temperature, vibration and other rigorous testing to ensure product stability and service life.

- CE certified to meet the needs of overseas markets.

- Back gauge control

- BUS mode control servo system

- Stroke length limitation

- Double programmable digital output

- Program memory of up to 40 programs up to 25 steps per program

- One side positioning

- Retract function

- Mm/Inch

- Chinese/English

- Bright LCD 128 x 64 display

- Back gauge control

- Gap control

- Stroke length limitation

- Actual and Programmed position visualization

- Stock counter

- Programmable up to 100 steps

- Panel-based housing

- Servo control / inverter / 2-speed AC control

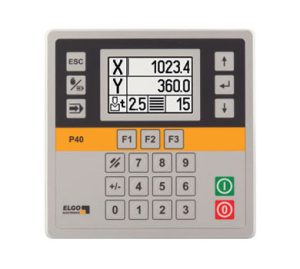

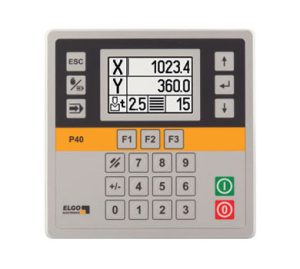

P40 Position Controller For 1 Or 2 Axes Position Controller For Metal Or Woodworking Machines

- One- or two-axis version

- LCD display

- Easy handling

- Multi-lingual menu navigation

- Option PID analog output available

- Reference run

- Manual-, single- and program mode

- Machine stronger welding structure, high precision and more peacefully color design and comfortable usage.

- Referring to man-machine engineering design backside all with safety guard guarantees operations safety.

- American world-famous brand for hydraulic pump. It performs well and provides great power for the whole system. Using Sunny pump ensures the pump service life and lower working noise.

Ensure machine stability, high quality electric parts can perform well even the electricity is not stable and customs can easily get the replacement anywhere in the world.

- Electrical components and materials conform to international standards, safe and reliable, long life, strong anti-interference ability.

- Removable foot switch operation is provided.

- The electronic control components are of high quality and famous brand.

- The machine adopts ac 380V three-phase four-wire power supply, and the control circuit is ac 220V voltage.

- The main circuit of the motor has short circuit, overload and phase loss protection.

- The operation button is installed on the button table of the machine tool, and the electrical switch and indicator light are installed in the special electrical control box.

- The stop button of the oil pump is also the general button of the machine tool. When the oil pump stops working, the whole machine tool stops working.

- The machine is equipped with corresponding inching control button and emergency stop button.

- Guarantees the machine service life, and reduce the noise when working.

- Schneider rear emergency shutdown switch & stroke switch.

- The EMB Casing Tube and connectors effectively reduce the adds against welding slag jamming the valves and affect oil flowing.

- High precise backgauge, equipped with Taiwan HIWIN ball screw and polished rod structure.

- Enhancing the service life and operational sensitivity and never broken up.

- Adjust the cutting blade gap by motor according to the thickness of metal sheet, can get better cutting performance. Rapid adjustment mechanism for rearranging blade clearance is easy to operate by hand, realizing stepless adjustment of blade clearance.

- Rolling steel ball of workbench can reduce friction, protect the workpiece surface. Delicate design is convenient for cutting petty materials by hand.

- Front positioning device, setting verticality and positioning device on the left-most front support, guaranteeing the cutting precision, easy operation, practical and efficient.

- High Precision Back gauge is equipped with fine ball screw and guide linear.

- Back gauge adopts horizontal installation shell structure with high stability, singe shell double guide rail, high precision, X-axixs drive, automatic CNC system.

QC12Y Swing Beam Shearing Machines with E21 Controller

The hydraulic swing beam shearing machine combines performance and simplicity. The robust steel welded machine frame ensures high reliability and excellent cutting quality. The hydraulic shears for sale are engineered to have the most optimized cutting angle which provides the least distortion when cutting the widest variety of materials. The low cutting angle on this type of shears allows limiting sheet metal twist and bow.

Model: QC12Y

Material: Stainless steel, mild steel, aluminum

Thickness: 0.1-20 mm

Width: 2500-600 0mm

Controller: E200S(E21S/DAC310/DAC360S/P40 Optional)

- The hydraulic swing beam shear is the perfect solution for cutting sheet metal with thickness between 4-35mm and length from 2500 to 8000 mm.

- Adopt advanced hydraulic system, reliable and easy for maintenance.

- The rear stopper is fitted with coder and digital display system, real-time display of material position.

- Multi-step programming function, automatic operation and continuous positioning of rear baffle, automatic adjustment of position of rear baffle.

- Shear counting function, real-time display of the number of shears, power off memory after the location of the block, procedures and parameters.

- Assembly precision ball screw, linear guide rail, to ensure the positioning accuracy, high machining precision.

- Safety Standards(2006/42/EC):

1.EN 12622:2009 + A1:2013

2.EN ISO 12100:2010

3.EN 60204-1:2006+A1:2009 - Front finger Protection (Safety light curtain).

- South Korea Kacon Foot Switch (Level 4 of safety).

- Back metal safe fence with CE standards.

- Safety relay with Monitor the pedal switch and safety protection.

Detailed description

- HD LCD display, with both Chinese and English language options, a display programming parameter, faster and more convenient programming

- Back gauge control:Smart positioning, can also be manually adjusted as needed to remove the mechanical hand positioning device.

- Cut Stroke: Built-shearing time relay, simple operation, cost savings

- Shear angle: Built shear angle adjustment function, eliminating the angle indicators and buttons

- Blade gap: encoder feedback, time display blade gap size, simple operation

- Having a key parameter backup and restore functionality, you can always restore the parameters as required, reducing maintenance costs

- All keys on the panel are micro-switches, through EMC, high temperature, vibration and other rigorous testing to ensure product stability and service life.

- CE certified to meet the needs of overseas markets.

- Back gauge control

- BUS mode control servo system

- Stroke length limitation

- Double programmable digital output

- Program memory of up to 40 programs up to 25 steps per program

- One side positioning

- Retract function

- Mm/Inch

- Chinese/English

- Bright LCD 128 x 64 display

- Back gauge control

- Gap control

- Stroke length limitation

- Actual and Programmed position visualization

- Stock counter

- Programmable up to 100 steps

- Panel-based housing

- Servo control / inverter / 2-speed AC control

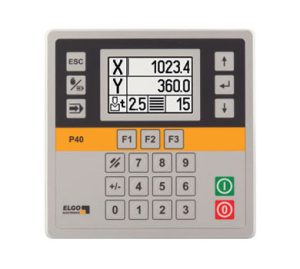

P40 Position Controller For 1 Or 2 Axes Position Controller For Metal Or Woodworking Machines

- One- or two-axis version

- LCD display

- Easy handling

- Multi-lingual menu navigation

- Option PID analog output available

- Reference run

- Manual-, single- and program mode

- Machine stronger welding structure, high precision and more peacefully color design and comfortable usage.

- Referring to man-machine engineering design backside all with safety guard guarantees operations safety.

- American world-famous brand for hydraulic pump. It performs well and provides great power for the whole system. Using Sunny pump ensures the pump service life and lower working noise.

Ensure machine stability, high quality electric parts can perform well even the electricity is not stable and customs can easily get the replacement anywhere in the world.

- Electrical components and materials conform to international standards, safe and reliable, long life, strong anti-interference ability.

- Removable foot switch operation is provided.

- The electronic control components are of high quality and famous brand.

- The machine adopts ac 380V three-phase four-wire power supply, and the control circuit is ac 220V voltage.

- The main circuit of the motor has short circuit, overload and phase loss protection.

- The operation button is installed on the button table of the machine tool, and the electrical switch and indicator light are installed in the special electrical control box.

- The stop button of the oil pump is also the general button of the machine tool. When the oil pump stops working, the whole machine tool stops working.

- The machine is equipped with corresponding inching control button and emergency stop button.

- Guarantees the machine service life, and reduce the noise when working.

- Schneider rear emergency shutdown switch & stroke switch.

- The EMB Casing Tube and connectors effectively reduce the adds against welding slag jamming the valves and affect oil flowing.

- High precise backgauge, equipped with Taiwan HIWIN ball screw and polished rod structure.

- Enhancing the service life and operational sensitivity and never broken up.

- Adjust the cutting blade gap by motor according to the thickness of metal sheet, can get better cutting performance. Rapid adjustment mechanism for rearranging blade clearance is easy to operate by hand, realizing stepless adjustment of blade clearance.

- Rolling steel ball of workbench can reduce friction, protect the workpiece surface. Delicate design is convenient for cutting petty materials by hand.

- Front positioning device, setting verticality and positioning device on the left-most front support, guaranteeing the cutting precision, easy operation, practical and efficient.

- High Precision Back gauge is equipped with fine ball screw and guide linear.

- Back gauge adopts horizontal installation shell structure with high stability, singe shell double guide rail, high precision, X-axixs drive, automatic CNC system.

QC12Y Swing Beam Shearing Machines with E21 Controller

The hydraulic swing beam shearing machine combines performance and simplicity. The robust steel welded machine frame ensures high reliability and excellent cutting quality. The hydraulic shears for sale are engineered to have the most optimized cutting angle which provides the least distortion when cutting the widest variety of materials. The low cutting angle on this type of shears allows limiting sheet metal twist and bow.

Model: QC12Y

Material: Stainless steel, mild steel, aluminum

Thickness: 0.1-20 mm

Width: 2500-600 0mm

Controller: DAC310(E21S/E200S/DAC360S/P40 Optional)

- The hydraulic swing beam shear is the perfect solution for cutting sheet metal with thickness between 4-35mm and length from 2500 to 8000 mm.

- Adopt advanced hydraulic system, reliable and easy for maintenance.

- The rear stopper is fitted with coder and digital display system, real-time display of material position.

- Multi-step programming function, automatic operation and continuous positioning of rear baffle, automatic adjustment of position of rear baffle.

- Shear counting function, real-time display of the number of shears, power off memory after the location of the block, procedures and parameters.

- Assembly precision ball screw, linear guide rail, to ensure the positioning accuracy, high machining precision.

- Safety Standards(2006/42/EC):

1.EN 12622:2009 + A1:2013

2.EN ISO 12100:2010

3.EN 60204-1:2006+A1:2009 - Front finger Protection (Safety light curtain).

- South Korea Kacon Foot Switch (Level 4 of safety).

- Back metal safe fence with CE standards.

- Safety relay with Monitor the pedal switch and safety protection.

Detailed description

- HD LCD display, with both Chinese and English language options, a display programming parameter, faster and more convenient programming

- Back gauge control:Smart positioning, can also be manually adjusted as needed to remove the mechanical hand positioning device.

- Cut Stroke: Built-shearing time relay, simple operation, cost savings

- Shear angle: Built shear angle adjustment function, eliminating the angle indicators and buttons

- Blade gap: encoder feedback, time display blade gap size, simple operation

- Having a key parameter backup and restore functionality, you can always restore the parameters as required, reducing maintenance costs

- All keys on the panel are micro-switches, through EMC, high temperature, vibration and other rigorous testing to ensure product stability and service life.

- CE certified to meet the needs of overseas markets.

- Back gauge control

- BUS mode control servo system

- Stroke length limitation

- Double programmable digital output

- Program memory of up to 40 programs up to 25 steps per program

- One side positioning

- Retract function

- Mm/Inch

- Chinese/English

- Bright LCD 128 x 64 display

- Back gauge control

- Gap control

- Stroke length limitation

- Actual and Programmed position visualization

- Stock counter

- Programmable up to 100 steps

- Panel-based housing

- Servo control / inverter / 2-speed AC control

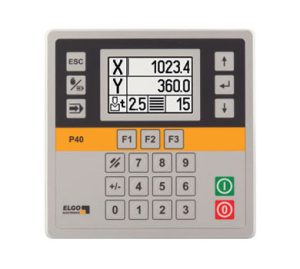

P40 Position Controller For 1 Or 2 Axes Position Controller For Metal Or Woodworking Machines

- One- or two-axis version

- LCD display

- Easy handling

- Multi-lingual menu navigation

- Option PID analog output available

- Reference run

- Manual-, single- and program mode

- Machine stronger welding structure, high precision and more peacefully color design and comfortable usage.

- Referring to man-machine engineering design backside all with safety guard guarantees operations safety.

- American world-famous brand for hydraulic pump. It performs well and provides great power for the whole system. Using Sunny pump ensures the pump service life and lower working noise.

Ensure machine stability, high quality electric parts can perform well even the electricity is not stable and customs can easily get the replacement anywhere in the world.

- Electrical components and materials conform to international standards, safe and reliable, long life, strong anti-interference ability.

- Removable foot switch operation is provided.

- The electronic control components are of high quality and famous brand.

- The machine adopts ac 380V three-phase four-wire power supply, and the control circuit is ac 220V voltage.

- The main circuit of the motor has short circuit, overload and phase loss protection.

- The operation button is installed on the button table of the machine tool, and the electrical switch and indicator light are installed in the special electrical control box.

- The stop button of the oil pump is also the general button of the machine tool. When the oil pump stops working, the whole machine tool stops working.

- The machine is equipped with corresponding inching control button and emergency stop button.

- Guarantees the machine service life, and reduce the noise when working.

- Schneider rear emergency shutdown switch & stroke switch.

- The EMB Casing Tube and connectors effectively reduce the adds against welding slag jamming the valves and affect oil flowing.

- High precise backgauge, equipped with Taiwan HIWIN ball screw and polished rod structure.

- Enhancing the service life and operational sensitivity and never broken up.

- Adjust the cutting blade gap by motor according to the thickness of metal sheet, can get better cutting performance. Rapid adjustment mechanism for rearranging blade clearance is easy to operate by hand, realizing stepless adjustment of blade clearance.

- Rolling steel ball of workbench can reduce friction, protect the workpiece surface. Delicate design is convenient for cutting petty materials by hand.

- Front positioning device, setting verticality and positioning device on the left-most front support, guaranteeing the cutting precision, easy operation, practical and efficient.

- High Precision Back gauge is equipped with fine ball screw and guide linear.

- Back gauge adopts horizontal installation shell structure with high stability, singe shell double guide rail, high precision, X-axixs drive, automatic CNC system.

QC12Y Swing Beam Shearing Machines with E21 Controller

The hydraulic swing beam shearing machine combines performance and simplicity. The robust steel welded machine frame ensures high reliability and excellent cutting quality. The hydraulic shears for sale are engineered to have the most optimized cutting angle which provides the least distortion when cutting the widest variety of materials. The low cutting angle on this type of shears allows limiting sheet metal twist and bow.

Model: QC12Y

Material: Stainless steel, mild steel, aluminum

Thickness: 0.1-20 mm

Width: 2500-600 0mm

Controler: DAC360S(E21S/E200S/DAC310/P40 Optional)

- The hydraulic swing beam shear is the perfect solution for cutting sheet metal with thickness between 4-35mm and length from 2500 to 8000 mm.

- Adopt advanced hydraulic system, reliable and easy for maintenance.

- The rear stopper is fitted with coder and digital display system, real-time display of material position.

- Multi-step programming function, automatic operation and continuous positioning of rear baffle, automatic adjustment of position of rear baffle.

- Shear counting function, real-time display of the number of shears, power off memory after the location of the block, procedures and parameters.

- Assembly precision ball screw, linear guide rail, to ensure the positioning accuracy, high machining precision.

- Safety Standards(2006/42/EC):

1.EN 12622:2009 + A1:2013

2.EN ISO 12100:2010

3.EN 60204-1:2006+A1:2009 - Front finger Protection (Safety light curtain).

- South Korea Kacon Foot Switch (Level 4 of safety).

- Back metal safe fence with CE standards.

- Safety relay with Monitor the pedal switch and safety protection.

Detailed description

- HD LCD display, with both Chinese and English language options, a display programming parameter, faster and more convenient programming

- Back gauge control:Smart positioning, can also be manually adjusted as needed to remove the mechanical hand positioning device.

- Cut Stroke: Built-shearing time relay, simple operation, cost savings

- Shear angle: Built shear angle adjustment function, eliminating the angle indicators and buttons

- Blade gap: encoder feedback, time display blade gap size, simple operation

- Having a key parameter backup and restore functionality, you can always restore the parameters as required, reducing maintenance costs

- All keys on the panel are micro-switches, through EMC, high temperature, vibration and other rigorous testing to ensure product stability and service life.

- CE certified to meet the needs of overseas markets.

- Back gauge control

- BUS mode control servo system

- Stroke length limitation

- Double programmable digital output

- Program memory of up to 40 programs up to 25 steps per program

- One side positioning

- Retract function

- Mm/Inch

- Chinese/English

- Bright LCD 128 x 64 display

- Back gauge control

- Gap control

- Stroke length limitation

- Actual and Programmed position visualization

- Stock counter

- Programmable up to 100 steps

- Panel-based housing

- Servo control / inverter / 2-speed AC control

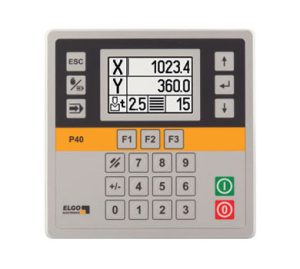

P40 Position Controller For 1 Or 2 Axes Position Controller For Metal Or Woodworking Machines

- One- or two-axis version

- LCD display

- Easy handling

- Multi-lingual menu navigation

- Option PID analog output available

- Reference run

- Manual-, single- and program mode

- Machine stronger welding structure, high precision and more peacefully color design and comfortable usage.

- Referring to man-machine engineering design backside all with safety guard guarantees operations safety.

- American world-famous brand for hydraulic pump. It performs well and provides great power for the whole system. Using Sunny pump ensures the pump service life and lower working noise.

Ensure machine stability, high quality electric parts can perform well even the electricity is not stable and customs can easily get the replacement anywhere in the world.

- Electrical components and materials conform to international standards, safe and reliable, long life, strong anti-interference ability.

- Removable foot switch operation is provided.

- The electronic control components are of high quality and famous brand.

- The machine adopts ac 380V three-phase four-wire power supply, and the control circuit is ac 220V voltage.

- The main circuit of the motor has short circuit, overload and phase loss protection.

- The operation button is installed on the button table of the machine tool, and the electrical switch and indicator light are installed in the special electrical control box.

- The stop button of the oil pump is also the general button of the machine tool. When the oil pump stops working, the whole machine tool stops working.

- The machine is equipped with corresponding inching control button and emergency stop button.

- Guarantees the machine service life, and reduce the noise when working.

- Schneider rear emergency shutdown switch & stroke switch.

- The EMB Casing Tube and connectors effectively reduce the adds against welding slag jamming the valves and affect oil flowing.

- High precise backgauge, equipped with Taiwan HIWIN ball screw and polished rod structure.

- Enhancing the service life and operational sensitivity and never broken up.

- Adjust the cutting blade gap by motor according to the thickness of metal sheet, can get better cutting performance. Rapid adjustment mechanism for rearranging blade clearance is easy to operate by hand, realizing stepless adjustment of blade clearance.

- Rolling steel ball of workbench can reduce friction, protect the workpiece surface. Delicate design is convenient for cutting petty materials by hand.

- Front positioning device, setting verticality and positioning device on the left-most front support, guaranteeing the cutting precision, easy operation, practical and efficient.

- High Precision Back gauge is equipped with fine ball screw and guide linear.

- Back gauge adopts horizontal installation shell structure with high stability, singe shell double guide rail, high precision, X-axixs drive, automatic CNC system.

QC12Y Swing Beam Shearing Machines with E21 Controller

The hydraulic swing beam shearing machine combines performance and simplicity. The robust steel welded machine frame ensures high reliability and excellent cutting quality. The hydraulic shears for sale are engineered to have the most optimized cutting angle which provides the least distortion when cutting the widest variety of materials. The low cutting angle on this type of shears allows limiting sheet metal twist and bow.

Model: QC12Y

Material: Stainless steel, mild steel, aluminum

Thickness: 0.1-20 mm

Width: 2500-600 0mm

Controler: P40(E21S/E200S/DAC310/DAC360S Optional)

- The hydraulic swing beam shear is the perfect solution for cutting sheet metal with thickness between 4-35mm and length from 2500 to 8000 mm.

- Adopt advanced hydraulic system, reliable and easy for maintenance.

- The rear stopper is fitted with coder and digital display system, real-time display of material position.

- Multi-step programming function, automatic operation and continuous positioning of rear baffle, automatic adjustment of position of rear baffle.

- Shear counting function, real-time display of the number of shears, power off memory after the location of the block, procedures and parameters.

- Assembly precision ball screw, linear guide rail, to ensure the positioning accuracy, high machining precision.

- Safety Standards(2006/42/EC):

1.EN 12622:2009 + A1:2013

2.EN ISO 12100:2010

3.EN 60204-1:2006+A1:2009 - Front finger Protection (Safety light curtain).

- South Korea Kacon Foot Switch (Level 4 of safety).

- Back metal safe fence with CE standards.

- Safety relay with Monitor the pedal switch and safety protection.

Detailed description

- HD LCD display, with both Chinese and English language options, a display programming parameter, faster and more convenient programming

- Back gauge control:Smart positioning, can also be manually adjusted as needed to remove the mechanical hand positioning device.

- Cut Stroke: Built-shearing time relay, simple operation, cost savings

- Shear angle: Built shear angle adjustment function, eliminating the angle indicators and buttons

- Blade gap: encoder feedback, time display blade gap size, simple operation

- Having a key parameter backup and restore functionality, you can always restore the parameters as required, reducing maintenance costs

- All keys on the panel are micro-switches, through EMC, high temperature, vibration and other rigorous testing to ensure product stability and service life.

- CE certified to meet the needs of overseas markets.

- Back gauge control

- BUS mode control servo system

- Stroke length limitation

- Double programmable digital output

- Program memory of up to 40 programs up to 25 steps per program

- One side positioning

- Retract function

- Mm/Inch

- Chinese/English

- Bright LCD 128 x 64 display

- Back gauge control

- Gap control

- Stroke length limitation

- Actual and Programmed position visualization

- Stock counter

- Programmable up to 100 steps

- Panel-based housing

- Servo control / inverter / 2-speed AC control

P40 Position Controller For 1 Or 2 Axes Position Controller For Metal Or Woodworking Machines

- One- or two-axis version

- LCD display

- Easy handling

- Multi-lingual menu navigation

- Option PID analog output available

- Reference run

- Manual-, single- and program mode

- Machine stronger welding structure, high precision and more peacefully color design and comfortable usage.

- Referring to man-machine engineering design backside all with safety guard guarantees operations safety.

- American world-famous brand for hydraulic pump. It performs well and provides great power for the whole system. Using Sunny pump ensures the pump service life and lower working noise.

Ensure machine stability, high quality electric parts can perform well even the electricity is not stable and customs can easily get the replacement anywhere in the world.

- Electrical components and materials conform to international standards, safe and reliable, long life, strong anti-interference ability.

- Removable foot switch operation is provided.

- The electronic control components are of high quality and famous brand.

- The machine adopts ac 380V three-phase four-wire power supply, and the control circuit is ac 220V voltage.

- The main circuit of the motor has short circuit, overload and phase loss protection.

- The operation button is installed on the button table of the machine tool, and the electrical switch and indicator light are installed in the special electrical control box.

- The stop button of the oil pump is also the general button of the machine tool. When the oil pump stops working, the whole machine tool stops working.

- The machine is equipped with corresponding inching control button and emergency stop button.

- Guarantees the machine service life, and reduce the noise when working.

- Schneider rear emergency shutdown switch & stroke switch.

- The EMB Casing Tube and connectors effectively reduce the adds against welding slag jamming the valves and affect oil flowing.

- High precise backgauge, equipped with Taiwan HIWIN ball screw and polished rod structure.

- Enhancing the service life and operational sensitivity and never broken up.

- Adjust the cutting blade gap by motor according to the thickness of metal sheet, can get better cutting performance. Rapid adjustment mechanism for rearranging blade clearance is easy to operate by hand, realizing stepless adjustment of blade clearance.

- Rolling steel ball of workbench can reduce friction, protect the workpiece surface. Delicate design is convenient for cutting petty materials by hand.

- Front positioning device, setting verticality and positioning device on the left-most front support, guaranteeing the cutting precision, easy operation, practical and efficient.

- High Precision Back gauge is equipped with fine ball screw and guide linear.

- Back gauge adopts horizontal installation shell structure with high stability, singe shell double guide rail, high precision, X-axixs drive, automatic CNC system.